1982 Broadbent BL16HSK (16.375" Bore)

Sold

1982 Broadbent BL16HSK (16.375" Bore)

Location:Mississippi

Description

(2) 30" 4-Jaw Chuck with 15" Hole Through the Chuck Hydraulic Taper Attachment 20 Degree Included Angle Range 20" Max Length of Taper Hydraulic Semi-Automatic Threading Auto Kickout Trip Rail Mounted on the Front of the Machine for Auto Tool Withdrawl Stop Feed & Return Saddle to Start of Cut Auto Cycle Inch/Metric Threading 2 HP Rapid Traverse Motor Rapid Traverse Electro Magnetic Clutch Tailstock Coolant Pump

240/480V Electrics

Hydraulic Tank (dimensions 26" (L) x 12" (W) x 25" (H))

Electrical Cabinet (dimensions 33" (L) x 20" (W) x 66" (H))

**This machine is currently NOT under power, and is NOT able to be put to power, but was running fine at most recent use**

Specifications

| Manufacturer | Broadbent |

| Model | BL16HSK (16.375" Bore) |

| Year | 1982 |

| Condition | Used |

| Stock Number | 103666 |

| Chuck Size | (2) 30" 4 Jaw w/ 15" bore |

| Maximum Swing over Bed | 34" |

| Maximum Swing Over Cross Slide | 25.5" |

| Maximum Swing in Gap | 56" |

| Length Of Gap | 17" |

| Maximum Distance Between Centers | 120" |

| Spindle Bore | 16.375" |

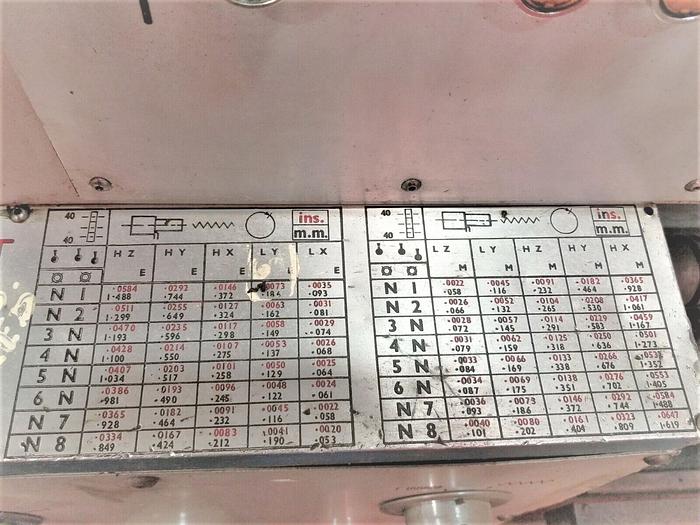

| Spindle Speeds | 21 - 350 RPM |

| Spindle Motor | 30 HP |

| Tool Post Type | 4 Way Post |

| Tailstock Bore Taper | MT #5 |

| Tailstock Quill Travel / Quill Diameter | 11.03" / 3.94" |

| Machine Dimensions | 190" x 82" x 66" machine only |

| Machine Weight | 38,000 lbs. |