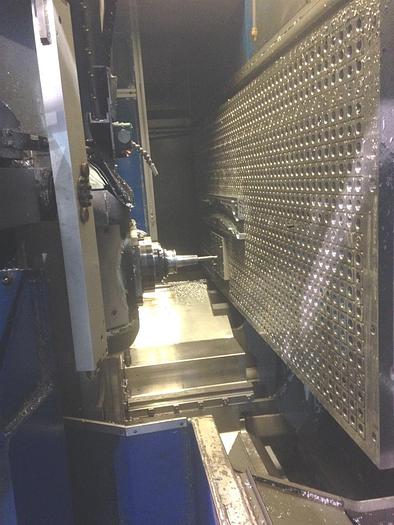

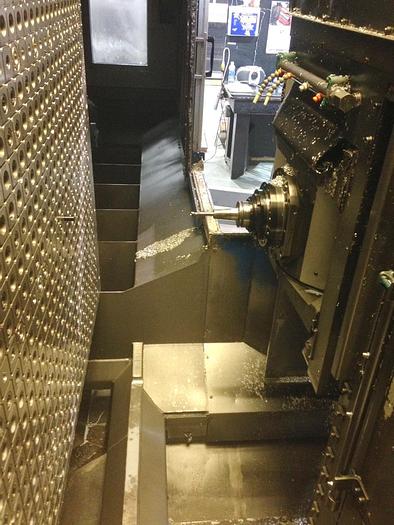

2000 Marwin Automax II

No longer available

2000 Marwin Automax II

$249,500 (USD)

Location:Dundee, FL

Description

2 Pallet Changer System

5 Axis Capability

B Axis Head

A Axis Head

Probing System

27,000 RPM Spindle

60 Station Tool Changer

Chip Conveyor

Scale Feedback

RS-232C Port for DNC Interface

3.5" Floppy Disk Drive

All Available Manuals

NEW PRICE of $ 1,636,000

Specifications

| Manufacturer | Marwin |

| Model | Automax II |

| Year | 2000 |

| Condition | Used |

| Stock Number | 105142 |

| Quantity | 1 |

| Control | Fanuc 160iM |